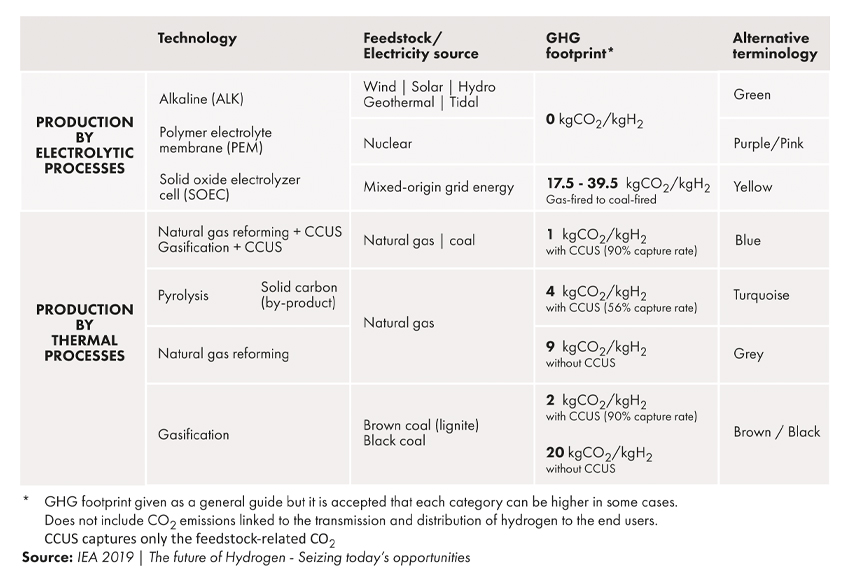

Electrolytic processes

Low temperature electrolysis (LTE)

The electrolysis process uses electricity to split water into hydrogen and oxygen molecules. A typical electrolyser cell consists of two electrodes

(cathode and anode) and a conducting electrolyte. The functioning of different types of electrolysers differs depending on the electrolyte material,

as explained below.

The type of cell used determines the operating temperature for electrolysers. LTE refers to electrolysis at operating

temperatures below approximately 300°C and typically uses alkaline water electrolysis (AWE) cells or polymer electrolyte membrane (PEM) cells.

Alkaline water electrolysis (AWE)

Alkaline water electrolysers employ alkaline liquid (usually aqueous KOH or NaOH) electrolytes which readily conduct electricity. In AWE cells, water

dissociation and hydrogen generation occurs at cathode and hydroxyl ions (OH¬-) transfer through the porous diaphragm producing water and oxygen at the

anode. These cells use inexpensive metals as electrode material and produce hydrogen of purity up to 99.9% at approximately 70-80% efficiency but

operate best at low current densities. Alkaline electrolysis is a mature technology where significant advances with respect to electrode and separating

diaphragm materials have improved the cost, efficiency, and durability of the cells. Alkaline electrolyzers however, do have higher start-up and

cycling times, and may require higher maintenance than PEM cells.

Polymer electrolyte membrane electrolysis (PEM)

Polymer electrolyte membrane (PEM) electrolysers use a solid ion-conducting membrane as the electrolyte instead of a liquid. In PEM cells, water

dissociation occurs at the anode and protons migrate selectively through the membrane generating hydrogen at the cathode. This type of electrolysis

has advantages such as smaller footprint, high current density, higher efficiency, low (20-80°C) temperature operation, higher dynamic operation,

and higher hydrogen purity. PEM cells, however, use high activity noble metal electrocatalysts which makes them more expensive than AWE cells.

High temperature steam electrolysis (HTSE)

High-temperature steam electrolysis employs high temperature (750-1000°C) for electrolysis of water. It utilizes inexpensive thermal energy from

nuclear reactors to convert water to steam and the dissociation reaction proceeds in vapor phase producing hydrogen. The energy demand for electrolysis

in vapor phase is lower thus consuming nearly 35% less electricity compared with LTE. The overall efficiency for HTSE is therefore higher than LTE.

In HTSE, high temperature electrolysis of steam at the cathode produces hydrogen molecules and oxygen ions that migrate through the solid oxide

electrolyte to form oxygen molecules at the anode. HTSE cells are also called solid oxide electrolyser cells (SOEC).

Power to X (PtX)

Besides being stored in batteries, electricity may be stored by converting it to another form of energy, including hydrogen. Power-to-X describes the

process of converting power generated from various renewable sources to other forms of energy carriers for use in other sectors or for storage and

then re-conversion to power when needed. The X in the terminology can refer to one of the following: power-to-ammonia, power-to-chemicals, power-to-fuel,

power-to-gas, power-to-hydrogen, power-to-liquid, power-to-methane, power-to-food, power-to-power, and power-to-syngas. For example – power-to-hydrogen

refers to the process of using electricity to split water and produce hydrogen through electrolysis. Similarly, power-to-gas refers to converting

renewable grid energy to gaseous carriers such as hydrogen or methane.